|

|

|

Applications :

|

| Custard Powder, Chocolate Powder, Coco Powder, Milk Powder, Cassava Flour, Roasted Ground Coffee, Spices, Talcum Powder packaging, Detergent Powder packing, Pharmaceutical Powders, Dyes and Coloring agents Powder, Distemper Powder, Pesticides etc. |

|

|

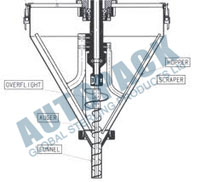

Discription :

|

| The vertical form fill seal machine with volumetric cup filler is best and most economical solution for packaging need of many industries. Our machine form sachets / pouches from film rolls, and fill the product into the sachets / pouches and finally sealing. |

|

|

Silent Features :

|

| – Sticky Powder Packing

– Fully Automatic

– Accurate Filling

– High Quality

– Food Grade Contact Parts |

|

| • High Accuracy on this filling system is achieved due to accurate design of Auger Screw, very sophisticated clutch brake and micro processor control system.

• Auger Filler can also be used as a individual filling machine for hand filling operation.

• All the contact parts of auger base (form fill seal) machine are made of Stainless steel (SS-304) which makes the parts corrosion resistant in addition to longer life.

• Auger Filler works on a hi-speed screw dosing principle which can be easily synchronized. |

|

|

Specifications :

|

|

| Sealing Type |

3 Side Sealing / 4 Side Sealing / Center Sealing (on Request) |

| Packing Size |

L : 40-120 mm or 100-240 mm (Film Length)

W: 20-160 mm or 20-220 mm (Film Width)

(Enlarged type can be made on order) |

| Packing Range |

0.5-30 gm , 30-50 gm , 50-100 gm , 100-300 gm (Depending on specific gravity of material to be packed) |

| Packing Material |

Any heat sealable laminated film such as Polyester/Poly, Paper/Poly, Glassine/Poly , Polyester/Met Polyester/Poly , Polyester/Foil/Poly , BOPP/Foil/Poly etc. |

| Motor |

1/2 H.P., 220V/ Single Phase/50 Hz. |

| Heater Load |

|

| 3 Side

Sealing/Centre Sealing

4 Side Sealing |

150W x 2 Nos.

300W x 2 Nos.

300W x 4 Nos. |

|

|

|

Features :

|

|

| • Fully automatic, compact and robust machine.

• Easy to change for different pouch sizes.

• Compact and easy to operate with all contact parts of stainless steel.

• Feeding head can be Cup / Auger / Weigh fillers – depending on the product to be packed.

• Top quality components and best workmanship.

• Simple and user friendly machine.

• Low maintenance and low operating cost.

• Digital Temperature Control system.

• All Product contact parts are made up of Stainless Steel (food grade).

• Fine packaging performance, low noise, clear sealing texture and strong sealing performance.

• Batch / Date Coding Device. |

|

| We can modify the machine as per specific customer requirements. |

|

|

Optional Devices :

|

| – Belt Conveyor

– Batch Coding Device

– Bucket Elevator

– Nitrogen Flushing Arrangement

– Level Sensor Device

– Ultra Violet System

– Servo Stabilizer |

|

|