|

Mono / Single Layer Nylon Film Extruder / PE Nylon Film Blowing Machine |

|

Applications :

Single Layer Nylon / Film blowing machine unit is used to blow various plastic films such as low-density polyethylene (LDPE), high-density polyethylene (HDPE) and linear low-density polyethylene (LLDPE). The films can be widely applied to packaging for industrial products, textiles, apparel and food and agricultural coverage.

|

|

| |

|

Three Layer Nylon Film Extruder / PE Three Layer Nylon Film Blowing Machine |

|

Applications :

Three-layer plastic co-extrusion film blowing composite machine unit is developed according to market demands, absorbs the advanced levels of like products at home and abroad in structure design, and can continuously blow various LDPE, HDPE, LLDPE, MLLDPE and packaging films which are 800/1,500mm in folding width and 0.08mm in thickness in a flat extrusion upper blowing method.

|

|

| |

|

Double Layer Nylon Extruder / PE Double Layer Nylon Film Blowing Machine |

|

Applications :

Double Layer Nylon Film Extruder is used for blowing the plastic laminated film of low density polyethylene(LDPE), high density polyethylene(HDPE)and linear low density polyethylene(LLDPE) etc., which are widely used for packing liquid, printed base material, products for export and industrial products, etc.

|

|

| |

|

Pure Water Nylon / Film Blowing Machine / Shopping Bag Extruder |

|

Discriptions :-

Film blowing machine unit with rotary machine head is used to blow various plastic films such as low-density polyethylene (LDPE), high-density polyethylene (HDPE) and linear low-density polyethylene (LLDPE). The films can be widely applied to packaging for liquid, printing composites, apparel and textiles and industrial products.

|

|

| |

|

Double Colour Nylon / Film Blowing Machine / Double Color Nylon Extruder

|

|

Discriptions :-

The two-color blown film machine unit is used to blow various low-density polyethylene (LDPE) and high-density polyethylene (HDPE) color strip plastic films. The plastic films can be widely used for civil and industrial packaging such as food, fruits, apparel, textiles and commodities.

|

|

| |

|

|

| |

|

|

| |

|

Nylon / Film Blowing Machine with Printing / Nylon Extruder with Offset Printing |

|

Discriptions :-

This machine unit is suitable for blowing low-density polyethylene (LDPE), high-density polyethylene (HDPE) and linear low-density polyethylene (LLDPE) plastic films and the like. The plastic films can be widely used for civil and industrial packaging such as food, apparel, trash bags, vest bags and the like.

|

|

|

| |

|

|

| |

|

|

| |

|

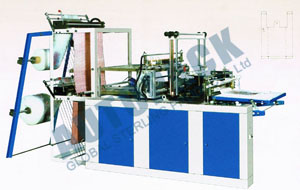

Double Layer Rolling Bag Making Machine / Rolling Bag Sealing & Cutting Machine |

|

Discriptions :-

The machine is specially designed point-cut rolling dual-purpose one for vest & flat bags and is controlled by a computer. The step servo setting length system reduces the sealing-cutting dimensions errors, and the installation of photo electric camera tracks help make the position of figure of printing bags accurate.

|

|

| |

|

|

| |

|

|

| |

|

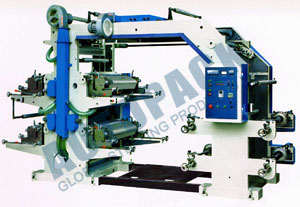

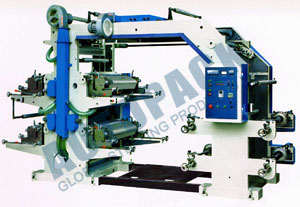

4 Color Flexo Printing Equipment / 4 Color Flexo Printing Machine |

|

Discriptions :-

This machine is suitable for printing such packing materials as polyethylene,

polypropylene plastic bag, glass paper and roll paper, etc. and it is a kind of ideal printing equipment for producing paper packing bag for food, supermarket handbag, vest bag and clothes bag, etc.

|

|

| |

|

|

| |

|

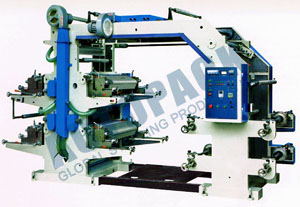

Multi Color Rotogravure Printing Machine |

|

Discriptions :-

Rotogravure Printing Machine is used in flexible packaging manufacturing and printing process including polyester, Nylon, Bopp, Foil, low and high density polyethylene polypro plane and paper with two sided printing facilities with high speed hot air dryers.

|

|

| |

|

Computerized Automatic Rotogravure Printing |

|

Discriptions :-

Machines in this series are applicable for continuous multi-color printing on rolling materials in good printing performance such as cellophane, BOPP, PET, PVC, PE, aluminum foil, and paper, broadly applied for all types of super-quality printed matters.

|

|

|

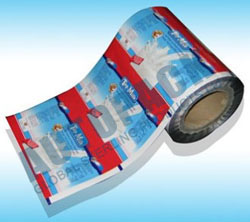

Production Samples

|

|

|

|

|

| |