|

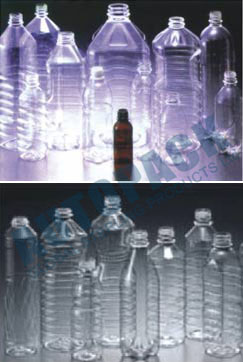

5 Gallon PET Jar Blowing Machine / 20 Ltr. Jar Blowing Machine

Semi – Auto PET Bottle Blowing Machine

|

||||||||||||||||||||||||||||||

|

Low labor consumption, high output, uniform bottle quality, easy and safe operation, and short changeover times make this system very efficient to operate, are the main features of our plastic machine range to meet the needs of various applications. It comes with one or two cavities and makes bottles or jars up to 5L at rates around 1200 bottles/hr |

||||||||||||||||||||||||||||||

|

Specification : – |

||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||

|

Oil Filling Machines

|

||||||||||||||||

|

||||||||||||||||

|

||||||||||||||||

Hand Sealers

|

||||||||||||||||||||||||

| Impulse sealers fire a short burst of electricity through a specially designed heating wire to fuse the inner walls of bags. The length of the seal time will depend on the sealing characteristics of the bag being sealed.

The sealing process is simple: The operator places the bag between the sealing jaws and presses the hand lever thus activating the unit. The seal process ends automatically once the preset seal time is reached. The operator retrieves the sealed bag and repeats the process. Bags are sealed repeatedly and uniformly. |

||||||||||||||||||||||||

Specification :- |

||||||||||||||||||||||||

|

||||||||||||||||||||||||

|

|

||||||||||||||||||||||||

|

||||||||||||||||||||||||

|

||||||||||||||||||||||||

Suction Filling Machine / Timer Filling Machine

|

|||||||||||||||||

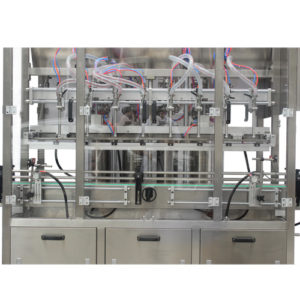

8 Head Oil Filling Machine

|

|||||||||||||||||||||||

|

|||||||||||||||||||||||

|

|||||||||||||||||||||||

Automatic Oil Filling Machine / Automatic Oil Filler

|

||||||||||||||||

| Suitable For Filling : Lubricant oil, Edible Oil, Motor oil, Essential Oil, Engine Oil, Cooking Oil, Liquid Soaps, Liquor. | ||||||||||||||||

|

Technical Specifications:- |

||||||||||||||||

|

||||||||||||||||

| We can customize the machine as per customer’s requirement. | ||||||||||||||||

|

||||||||||||||||

|

||||||||||||||||

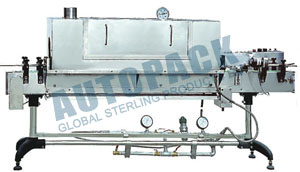

Shrink Wrapping / Packing Machines

|

|||||||||||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||||||||||

Induction Sealing Machines

|

||||||||||||||

|

||||||||||||||

|

Induction Sealing Machine – Hand Model

|

||||||||||||||

Applications :- |

||||||||||||||

ChemicalsInsecticides, Pesticides, Adhesives, Photo Chemicals, Flux, Household Cleaning Products AutomotiveCoolants, Lubricants, Break Oil. DairyMilk, Yogurt. CosmeticsCreams, Scrubs, Shampoos, Lotions, Hair Oil. DentalToothpaste, Filling Cement. Health CareNeutracueticals, Herbal Powders PharmaceuticalsTablets, Capsules, Oral Suspensions, Syrups, Dry Syrups. FoodJams, Edible Oil, Food Flavors, ketchup, Lozenges, Confectionary, Salad Dressings, Pickles, BeveragesPowder Drinks, Flavored Milk, Juices, Fruit Syrups, Coffee Concentrate, Tea Leaves.

Benefits Of Induction Cap SealingBetter Quality• No Leakage • Increased Shelf life • Tamper Evident Higher Productivity• Suitable for automated lines • Conveyorized production possible Reduced Costs• No product recalls • Uniform sealing • No operator required |

||||||||||||||

|

||||||||||||||

Features : – |

||||||||||||||

| 1, Full stainless steel structure, digital display, split structure, ease of use;

2, Water cooling circulation system, keeping the power of components at a desirable temperature range for more reliable & continuous operation; 3, Under/over-voltage protection, over-current protection, overheat protection, etc; 4, High sealing power, fast sealing, designed for high-speed process lines. |

||||||||||||||

Specification : – |

||||||||||||||

|

||||||||||||||

|

||||||||||||||

|