|

Stretch Wrapping Machine

|

|

|||

|

|||

|

||

Vertical Band Sealing Machine

|

||||||||||

Vertical Band Sealing Machine |

||||||||||

|

Global Marketing Empire is counted among the leading manufacturers and suppliers of optimum quality Vertical Band Sealing Machine . Sourced from trustworthy vendors, good quality raw materials are used in the manufacturing of these sealers. Known for their smooth functionality, high speed sealing and high hassle-free performance, offered machines are made available with an adjustable conveyor. |

||||||||||

|

Specifications :

|

||||||||||

Silent Features : |

||||||||||

|

~ Conveyor can be adjusted up and down to accommodate various heights of the pouch ~ Efficient forced cooling system for highly integrated sealing ~ High speed sealing system, with no holding time of pouch due to continuous conveyor |

||||||||||

|

|

||||

|

||||

|

||||

|

|

Bleach Filling Machine

|

|||||||||||||||

Cream Filling Machine

Global Marketing Empire offers our clients a spectrum of cream filling machines which are widely used in diverse industries which are engaged in filling substance or creams. Our range is high in demand owing to its high end features such as trouble free performance and high functionality. (more…)

Vacuum Packing Machine

Global Marketing Empire offering a high quality range of Vacuum Packing Machine. These machines offer prevention from oxidation, dampness, fungus, molds, rusting etc. These machines are fabricated using premium quality material. These machines are widely appreciated for Quality Looks, Compact size. Our valuable clients can available these machinery from us at competitive market rates.

Application

• Cheese, Paneer,

• Soya Based Products, Tofu

• Food Grains, rice, Perishable Food items

• Meat products

• Sea food, Smoked Fish

• Electronic components

• Hardware

Features:

• Stainless steel

• Opening of lid automatically

• Operator friendly operation

• Robust construction

• Low maintenance

• Extend product shelf life

Vacuum Packing Machine are available in different models for diverse applications.

a) Vacuum Packing Machine Double chamber

b) Vacuum Packing Machine Single Chamber

c) Vacuum Packing Machine Table Top

1. Vacuum Packing Machine Double chamber

Description:

MRE-VP-DC-11 Double chambers vacuum packaging machine can complete the set programs of vacuum extraction, gas flushing (optional), sealing, printing, cooling and exhaust automatically. The products after packing can be prevented from oxidation, going mold, insects or getting damp, thus can be kept fresh for a longer time. Double chambers vacuum packaging adopt “BUSCH” vacuum pump.

Specification:

| Model Number | MRE-VP-DC-11 |

| Chamber Size | 570*540*118 mm |

| Packing Speed | 4 – 8 Pcs/min |

2. Vacuum Packing Machine Single Chamber

Description:

we are able to introduce an exclusive range of MRE-VP-DC-12 Single Chamber Vacuum Packager Machine. The offered packager uses 220 V 50 Hz voltage, and 1.5 KW of power for the production of word room size 420 X 440 X 115 mm and sealing length of 400 X 10 mm, and sealing speed of 1-4 pcs/min. The weight of the packager is 105kgs.

Specification:

| Model Number | MRE-VP-DC-12 |

| Chamber Size | 420*440*115 mm |

| Packing Speed | 1 – 4 Pcs/min |

3. Vacuum Packing Machine Table Top

Description:

We are leading manufacturer, supplier, and exporter of a wide range of MRE-VP-DC-12 Table Top Vacuum Packing Machine. Our these tabletop vacuum packing machines are widely used in various industries for packaging work. We offer these machines to our valuable clients at affordable price.

Specification:

| Model Number | MRE-VP-DC-13 |

| Chamber Size | 320*340*80 mm |

| Packing Speed | 1 – 4 Pcs/min |

|

|

Paste Filling Machine

Paste Filling Machine:

Global Marketing Empire offers our clients a spectrum of paste filling machines which are widely used in diverse industries which are engaged in filling substance or pastes. Our range is high in demand owing to its high end features such as trouble free performance and high functionality. Our range of paste filling machines includes cream filling machines, ointment filling machines, automatic paste filling machine and semi automatic paste filling machines.

PF – V II PF – V II Paste Filling Machine(Double Head) |

|

PF – V I |

PF – V II |

Video:

Product Images:

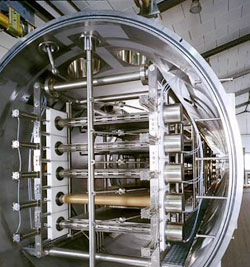

Continuous Vacuum Type Yam Powder Dryer / Vacuum Belt Dryer for food / chemicals

|

||||||||||||

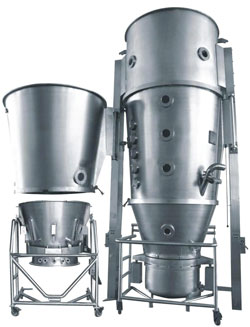

Fluid Bed Dryer for Powders / Chemicals / Pharmaceutical Fluid Bed Dryer

|

||||||||||||||

|

||||||||||||||

|

||||||||||||||