|

|

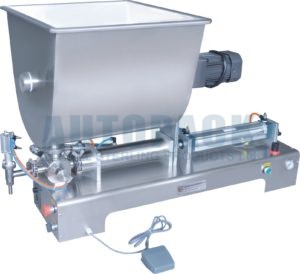

Paste Filling Machine |

Description :-

Global Marketing Empire offers our clients a spectrum of paste filling machines which are widely used in diverse industries which are engaged in filling substance or pastes. Our range is high in demand owing to its high end features such as trouble free performance and high functionality. Our range of paste filling machines includes cream filling machines, ointment filling machines, automatic paste filling machine and semi automatic paste filling machines.

|

|

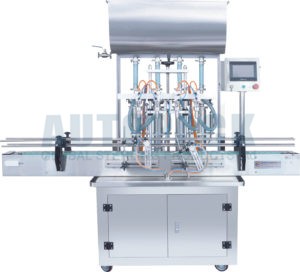

Hand Sanitizer Filling Machine |

Description :-

Global Marketing Empire offers our clients a spectrum of Hand Sanitizer Filling Machine which are widely used in diverse industries which are engaged in filling substance or creams. Our range is high in demand owing to its high end features such as trouble free performance and high functionality. Our range of Hand Sanitizer Filling Machine includes cream filling machines, ointment filling machines, automatic cream filling machine, Disinfection Liquid Filler and semi automatic cream filling machines.

|

|

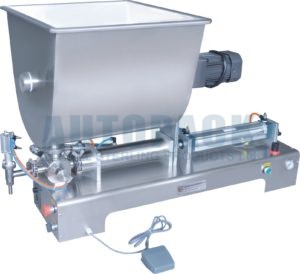

Semi Automatic Machine For Filling Sauces |

Description :-

Suitable for medicine, cosmetics, gels, food pastes and special industries. It is an ideal device for adhesive fluid filling.

The manual filling machine is specially designed for medium or small size enterprises, laboratory, hospital or beauty parlor, daily use chemical section.

|

|

Volumetric Liquid Filling Machine/Syrup Filling Machine |

Description :-

- used for filling liquidity is good material, such as water, oil, juice(no particles), liquid detergent, sauce, wine, liquid cream, etc.

- Suitable for various packing such as bottle, jar, can, cup, bag, barrels, etc.

|

|

|

Manual Table Top Cream, Ointment/Tube Filling Machine |

Description :-

Suitable for medicine, cosmetics, gels, food pastes and special industries. It is an ideal device for adhesive fluid filling.

The manual filling machine is specially designed for medium or small size enterprises, laboratory, hospital or beauty parlor, daily use chemical section.

Its structure is compact, easy to use, and all the contact parts which dip in the material are made of stainless steel and food grade Teflon.

Equipped with filling quantity adjusting device knob, quantitative filling and filling speed can be manually controlled.

|

|

Table Top Cream, Ointment/Tube Filling Machine |

Description :-

Suitable for medicine, cosmetics, gels, food pastes and special industries. It is an ideal device for adhesive fluid filling.

The manual filling machine is specially designed for medium or small size enterprises, laboratory, hospital or beauty parlor, daily use chemical section.

|

|

Cream Filling Machine With Mixer |

Description :-

- Be used for filling with particulate matter sauce,paste,liquid and other material.

- Full pneumatic control, easy to operate,remove and clean; Ideal equipment for filling inflammable, explosive materials.

|

|

Paste Filler With Jacked Tank With Mixer |

Description :-

The model of manual paste and liquid filling machine is widely used for Chemicals, Pharmaceuticals, Beverages, Pastes, Liquid’s volumetric filling.

This paste and liquid filling machine is a simple, volumetric filling.

This paste filling machine has accuracy filling & made of stainless steel to meet the food, pharmaceutical & health requirements.

|

|

|

Transfer Pump |

Description :-

Suitable for medicine, cosmetics, gels, food pastes and special industries. It is an ideal device for adhesive fluid filling.

The manual filling machine is specially designed for medium or small size enterprises, laboratory, hospital or beauty parlor, daily use chemical section.

|

|

Semi Automatic Liquid Filler With Weighing System |

Description :-

Suitable for medicine, cosmetics, gels, food pastes and special industries. It is an ideal device for adhesive fluid filling.

The manual filling machine is specially designed for medium or small size enterprises, laboratory, hospital or beauty parlor, daily use chemical section.

|

|

Corrosive Liquid Filler |

Description :-

Suitable for medicine, cosmetics, gels, food pastes and special industries. It is an ideal device for adhesive fluid filling.

The manual filling machine is specially designed for medium or small size enterprises, laboratory, hospital or beauty parlor, daily use chemical section.

|

|

Liquid Filler For Perfume |

Description :-

Suitable for medicine, cosmetics, gels, food pastes and special industries. It is an ideal device for adhesive fluid filling.

The manual filling machine is specially designed for medium or small size enterprises, laboratory, hospital or beauty parlor, daily use chemical section.

|

|

Production Samples

|

|

|