|

Industrial Chillers

|

||||||||||||||||||||||

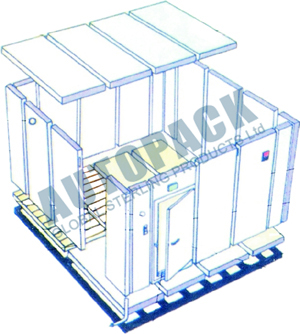

Cold Rooms, Cold Storage Room

|

|||||||||||||||||||||||||||

Ice Cubes Making Machine, Cube Ice Machine

Tube Ice Machines

|

|||

Features & Benefits of ICEBERG Tube ice machine are as follows: |

|||

| – Capacity from 1.5-55 tons/24 hours

– Packaged type equipment for 1.5 – 5 tons capacity – Good shape tubes and arrange on various sizes – Ammonia/ R22/ environment friendly refrigerant – Operate with high temperature make up water – Eligible to install in ambient temperature – Easy and low cost maintenance. – Simple to operate, long life and low energy. |

|||

|

|||

|

|||

Automatic Shell Ice Machine

|

||||||||

|

||||||||

|

||||||||

Automatic Ice Flake Machine

|

||||||||

|

||||||||

|

||||||||

Semi Automatic Ice Block Making Machine

|

|||

|

Ice blocks, standard sizes are: 4.5kg = 11.5 x 9.5 x 48cm 12.5kg = 15 x 13 x 70 cm 20kg = 25 x 13 x 70 cm 25kg = 30 x 13 x 70 cm

These blocks allow easy handling, they are neither too long, nor too heavy.

Production Capacity is available from 200kg – 2 Ton per day. |

|||

Features: |

|||

| – Copeland Refrigeration System to guarantee performance

– Thick enough heat insulation for water tank – Aluminum alloy made ice module – Customized ice size and cycle quantity – Water/air cooling for choose – Easy to Operate and Maintain – Refrigeration equipment supplier with rich experience – One stop solution for all cold chain equipments – We adopt high quality components to guarantee the quality – Professional team for solution installation and after-sale service.

We also provide different kinds for different purposes including Ice Cube Machine, Flake Ice Machines, Tube Ice Machine, Shell Ice, Industrial Chillers and Cold Rooms. |

|||

|

|||

|

|||

Automatic Pouch / Sachet Packing Machine (600ML)

|

|||||||||||||||||||||

|

|||||||||||||||||||||

|

|||||||||||||||||||||

Coding Ink / Fluids

|

|||||||||

Automatic Ice Block Making Machine

|

|||

|

Ice blocks, standard sizes are: 4.5kg = 11.5 x 9.5 x 48cm 12.5kg = 15 x 13 x 70 cm 20kg = 25 x 13 x 70 cm 25kg = 30 x 13 x 70 cm

These blocks allow easy handling, they are neither too long, nor too heavy.

Production Capacity is available from 200kg – 2 Ton per day. |

|||

Features: |

|||

| – Copeland Refrigeration System to guarantee performance

– Thick enough heat insulation for water tank – Aluminum alloy made ice module – Customized ice size and cycle quantity – Water/air cooling for choose – Easy to Operate and Maintain – Refrigeration equipment supplier with rich experience – One stop solution for all cold chain equipment – We adopt high quality components to guarantee the quality – Professional team for solution installation and after service.

We also provide different kinds for different purposes including Ice Cube Machine, Flake Ice Machines, Tube Ice Machine, Shell Ice, Industrial Chillers and Cold Rooms. |

|||

|

|||

|

|||