|

About Us |

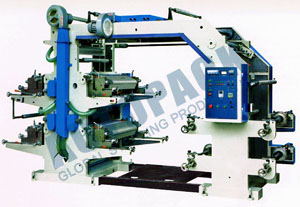

2 Color Flexo Printing Equipment / 2 Color Flexo Printing Machine

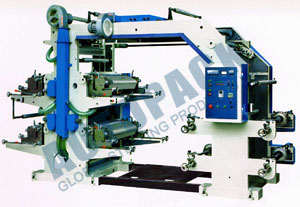

4 Color Flexo Printing Equipment / 4 Color Flexo Printing Machine

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Characteristics:

1. Easy operation, flexible starting, accurate colour register. 2. The meter counter can set printing quantity according to the requirements, Stop the machine automatically at the set quantity or when the material is cut off. 3. Lift and lower the printing plate cylinder manually, it will automatically stir the printing ink after lifting. 4. The printing ink is spread by the knurled cylinder with even ink colour. 5. Reliable drying system coordinated with high-speed rotation, it will automatically break circuit when the machine stops. 6. Continuous and adjustable longitudinal register device. 7. The imported frequency control of motor speed adapts to different printing speed. 8. There are inching/Stopping buttons on the plate roller base and material rolling rack so as to make it easy operate the machine when the plate is installed. |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Specifications : – |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Flexo Printing Machine / 6 Color Flexo Printing Machine

|

||||||||||||||||||||||||||||

|

Characteristics:

1. Easy operation, flexible starting, accurate colour register. 2. The meter counter can set printing quantity according to the requirements, Stop the machine automatically at the set quantity or when the material is cut off. 3. Lift and lower the printing plate cylinder manually, it will automatically stir the printing ink after lifting. 4. The printing ink is spread by the knurled cylinder with even ink colour. 5. Reliable drying system coordinated with high-speed rotation, it will automatically break circuit when the machine stops. 6. Continuous and adjustable longitudinal register device. 7. The imported frequency control of motor speed adapts to different printing speed. 8. There are inching/Stopping buttons on the plate roller base and material rolling rack so as to make it easy operate the machine when the plate is installed. |

||||||||||||||||||||||||||||

|

Specifications : – |

||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||

|

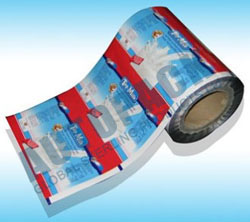

Automatic Nylon / Film Slitting Machine / Film Slitting and Rewinding Machine

|

||||||||||||||||||||||||||||||

|

Specifications : – |

||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||

|

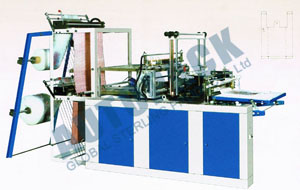

Double Layer Rolling Bag Making Machine / Rolling Bag Sealing & Cutting Machine

|

||||||||||||||||||||||||||||||

|

Specifications : – |

||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||

Four Line Film Sealing and Cutting Machine / Double Layer Four Line Film Sealing & Cutting Machine

|

||||||||||||||||||||||||||||||||||||||||||||||||

|

Specifications : – |

||||||||||||||||||||||||||||||||||||||||||||||||

|

Nylon / Film Sealing and Cutting Machine / Double Layer Film Sealing & Cutting Machine

|

||||||||||||||||||||||||||||||

|

Specifications : – |

||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||

Nylon / Film Blowing Machine with Printing / Nylon Extruder with Offset Printing

|

||||||||||||||||||||||||||||||||||||||||||||||||

|

Specifications : – |

||||||||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||||||

Nylon / Film Blowing Machine with Printing / Nylon Extruder with Gravure Printing

|

||||||||||||||||||||||||||||||||||||||||

|

Specifications : – |

||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||

Double Head Nylon / Film Blowing Machine / Double Head Nylon Extruder

|

|||||||||||||||||||||||||||||||||||||||||||||

|

Specifications : – |

|||||||||||||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||||||||||||