|

16 cavity Compression Cap Moulding / Making Machine |

Description :-

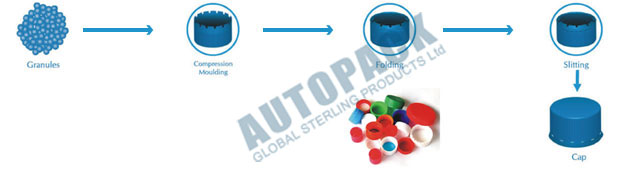

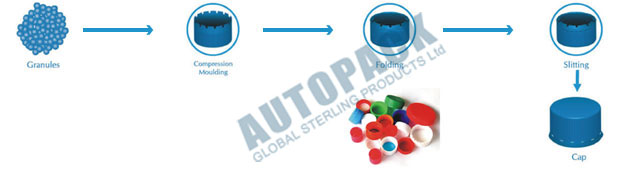

Compression Molding is a well known Technology, worldwide. Today, most of the caps for soft drinks and water, are produced on Compression Molding Machines, since this process uses air compressor to provide the pressure. The pressure is much higher, stable and provides even pressure to every mould. So the caps made by this process are smoother and with a tighter structure.

|

|

|

|

24 cavity Compression Cap Making / Moulding Machine |

Description :-

Compression Molding is a well known Technology, worldwide. Today, most of the caps for soft drinks and water, are produced on Compression Molding Machines, since this process uses air compressor to provide the pressure. The pressure is much higher, stable and provides even pressure to every mould. So the caps made by this process are smoother and with a tighter structure.

The cap production is much faster and of even quality and the power consumption is also much lesser than an injection molding machine.

|

|

|

|

32 cavity Compression Cap Moulding / Making Machine |

Description :-

Compression Molding is a well known Technology, worldwide. Today, most of the caps for soft drinks and water, are produced on Compression Molding Machines, since this process uses air compressor to provide the pressure. The pressure is much higher, stable and provides even pressure to every mould. So the caps made by this process are smoother and with a tighter structure.

|

|

|

|

Cap Folding Machine |

Description :-

This machine can make extension part of anti-theft ring fold inward, together with the advanced control of the air system and the latest PLC system to realize the automatic spout feeding, sorting & allocation. greatly improves the productivity effect. This machine effectively solves the problem of anti-theft ring infolding.

|

|

|