|

Applications:-

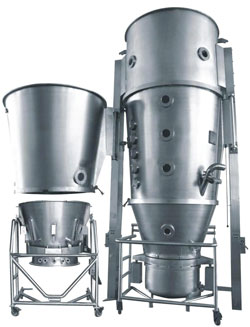

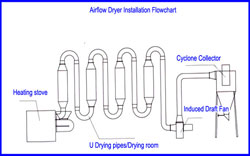

Industrial Hot Air Dryer for :

Fruits, Banana, Yam, Cassava, Apple, Papaya, Dried Fruits and Vegetables,

Pharmaceutical Products, Chemical Industry, Food Industry, Aquatic Products,

Traditional Medicines etc.

In conventional or surface heating, the process time is limited by the rate of heat flow into the body of the material from the surface as determined by its specific heat, thermal conductivity, density and viscosity. Surface heating is not only slow, but also non-uniform with the surfaces, edges and corners being much hotter than the inside of the material. Consequently, the quality of conventionally heated materials is variable and frequently inferior to the desired result.

Imperfect heating causes product rejections, wasted energy and extended process times that require large production areas devoted to ovens. Large ovens are slow to respond to needed temperature changes, take a long time to warm up and have high heat capacities and radiant losses. Their sluggish performance makes them slow to respond to changes in production requirements making their control difficult, subjective and expensive.

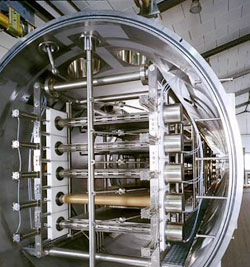

Conversely, with microwaves, heating the volume of a material at substantially the same rate is possible. This is known as volumetric heating. Energy is transferred through the material electro-magnetically, not as a thermal heat flux. Therefore, the rate of heating is not limited and the uniformity of heat distribution is greatly improved. Heating times can be reduced to less than one percent of that required using conventional techniques.

Features :-

Microwave dryer is a dryer which uses microwave to reduce the moisture from raw material. Unlike other external heating drying, microwave dryer for spice can dry the raw material from internal and external at the same time. Using this method, microwave dryer for spice can save drying time and avoid the raw material becoming metamorphism or coking at the overheat environment. The drying effect is very good, especially for the heat sensitive food.

Conventional means of heating and drying do not compare to the efficiency of an industrial microwave dryer. Incorporating high capacity, state-of-the-art microwave drying and heating equipment ensures that your products maintain quality while you experience double to triple the throughput achieved with conventional heating equipment.

The Main components of Microwave Dryer for Spice:

- Microwave generator system

- Microwave box

- Temperature controlling system

- Humidity controlling system

- Transmission system

- PLC and touch screen control system

- Humidity discharging system

- Electrical cabinets

- Cooling system

- Hot air recycling and circulatory system

|