|

Thermoforming Machine / Moulds Plastic Cup / Trays Moulds

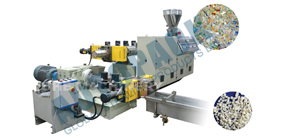

Plastic Granulators Machine / Plastic Re-Cycling Granulators

|

|||||||||||||||||

|

Screw & barrel is made up of high quality material with gas nitration & chrome plating that make screw & barrel to be anti acid & wear resisting – Wide range for single screw extruders ranging from 90mm – 140mm. – suitable for recycling L.D.P.E, H.D.P.E, P.P, A.B.S, Crystal, H.I.P.S, coloring – Barrel is cooled by air blower (optional) to keep barrel temperature stable & uniform for high performance extruding – Hydraulic screen changer ( optional ) is fitted at the die which reduces filter changing time to just 30 seconds. – Digital controllers are used in the control system as per customer’s requirement – Special helical extruder gearboxes are used for reduction with heavy thrust bearing – The palletizing is done by the strand cutter or die face cutter with water cooling – Granules & compounding P.V.C shoe grade & cable grade |

|||||||||||||||||

|

|||||||||||||||||

|

|||||||||||||||||

Plastic Granules Mixer / Plastic High Speed Mixer

|

||||||||||

|

||||||||||

|

||||||||||

Plastic Waste Sheet Grinding Machine / Plastic Sheet Crushing Machine

|

||||||||||||

|

||||||||||||

|

||||||||||||

Automatic Cup Stacking Machine / Plastic Cups Arranging Machine

|

||||||||||||

|

Specification |

||||||||||||

|

||||||||||||

|

||||||||||||

|

||||||||||||

Automatic Plastic Box Thermo Forming Machine / Automatic Plastic Tray forming / moulding machine

|

||||||||||||

|

Specification |

||||||||||||

|

||||||||||||

|

||||||||||||

|

||||||||||||

Automatic Plastic Spoon Thermo Forming Machine / Automatic spoon forming / moulding machine

|

||||||||||||

|

Specification |

||||||||||||

|

||||||||||||

|

||||||||||||

|

||||||||||||

Vacuum Forming Glass / Trays Making Machine / Vacuum Forming Machine for Cups

|

||||||||||||||||||||||||

|

Specification |

||||||||||||||||||||||||

|

||||||||||||||||||||||||

|

||||||||||||||||||||||||

|

||||||||||||||||||||||||

Glass / Trays Making Machine / Thermoforming Machine for Cups

|

||||||||||||||||||||||||

|

Specification |

||||||||||||||||||||||||

|

||||||||||||||||||||||||

|

||||||||||||||||||||||||

|

||||||||||||||||||||||||

PET Sheet Extruding Machine / PET Sheet Extruder

|

||||||

|

1. Advanced PLC control system is adopted, and equipped with large color LCD touch screen. Centralized control for the running of the complete machines. several teams of production running data can be stored; 2.Both screw and machine barrel adopted high quality alloy steel and nitrogen treatment to ensure the surface hardness and machining precision; 3.Rapid hydraulic net changing device is adopted, thus the production efficiency is high; 4.The structures of the divider and the T type die head are reasonable. The flow channel is advanced; shunting of each layer is steady and not mixed layer. The thickness can be adjusted. 5. Three rollers adopt horizontal structure so that the techniques of sheet production are more reasonable and improvable for its quality, adopt double-work position air shaft center rewinder device |

||||||

|

||||||

|

||||||