|

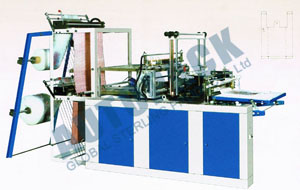

Double Layer Rolling Bag Making Machine / Rolling Bag Sealing & Cutting Machine

Four Line Film Sealing and Cutting Machine / Double Layer Four Line Film Sealing & Cutting Machine

|

||||||||||||||||||||||||||||||||||||||||||||||||

|

Specifications : – |

||||||||||||||||||||||||||||||||||||||||||||||||

|

Nylon / Film Sealing and Cutting Machine / Double Layer Film Sealing & Cutting Machine

|

||||||||||||||||||||||||||||||

|

Specifications : – |

||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||

Nylon / Film Blowing Machine with Printing / Nylon Extruder with Offset Printing

|

||||||||||||||||||||||||||||||||||||||||||||||||

|

Specifications : – |

||||||||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||||||

Nylon / Film Blowing Machine with Printing / Nylon Extruder with Gravure Printing

|

||||||||||||||||||||||||||||||||||||||||

|

Specifications : – |

||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||

Double Head Nylon / Film Blowing Machine / Double Head Nylon Extruder

|

|||||||||||||||||||||||||||||||||||||||||||||

|

Specifications : – |

|||||||||||||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||||||||||||

Double Colour Nylon / Film Blowing Machine / Double Color Nylon Extruder

|

||||||||||||||||||||||||||||

|

|

||||||||||||||||||||||||||||

Pure Water Nylon / Film Blowing Machine / Shopping Bag Extruder

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Specifications:- |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Double Layer Nylon Extruder / PE Double Layer Nylon Film Blowing Machine

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Specifications:- |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Three Layer Nylon Film Extruder / PE Three Layer Nylon Film Blowing Machine

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Discriptions :- | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Three-layer plastic co-extrusion film blowing composite machine unit is developed according to market demands, absorbs the advanced levels of like products at home and abroad in structure design, and can continuously blow various LDPE, HDPE, LLDPE, MLLDPE and packaging films which are 800/1,500mm in folding width and 0.08mm in thickness in a flat extrusion upper blowing method.

The films produced can be widely applied to light and heavy packaging for various fresh fruits, meat food, pickles, fresh milks and liquid beverage due to good barrier property, moisture preservation and prevention, rain, wind and frost resistance, oxygen insulation and oil resistance. |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Features:- 1. The machine head adopts a layering spiral core rod type to realize continuous 360°rotation. 2. The rapid filter screen replacing device has reasonable structure and reliable use, and is easy to replace filter screens. 3. The machine unit is equipped with various functional parts, such as length counting device, longitudinal cutting device, cooling water draining, nip rolls and edge cutting device. |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Specifications:- |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||