| No.1 SELLING INKJET CODING PRINTER IN JAPAN |

| Cost Effective, Reliable and High Quality Industrial Inkjet Printer for Your Coding and Marking Needs |

| Service Backup / Spares available in Nigeria and throughout West African Region |

| KGK Japan’s Leading Brand in Collaboration with Autopack – Nigeria is offering Continuous Inkjet Printing Machines |

| KGK continuous inkjet printing machines are more technologically advanced and cost-effective, which offer high reliability and quality at a good price / performance ratio.KGK is Japan’s leader in the coding and marking industry for both ink jet coders. We provide a complete line of industrial coders and supplies that are able to produce reliable codes at today’s production line speeds. KGK graphics systems provide reliable and cost-effective printing of addresses, personalized messages, bar codes and serialized numbers. |

|

|

|

| Printing Applications : |

- Printing Expiry and Manufacturing Dates at High Speeds

- Printing Product Information, Brand Logo and Product Description

- Printing lot codes, Batch numbers, Bar codes with Consistent Print Quality

- Printing on Primary Packaging like Wrappers, Foils, Pouches, Bottles, Containers

- Printing on almost all types of secondary packaging like Boxes, Cartons, Cases

- Printing Permanent / Temporary and Consistent Codes

|

|

|

| Suitable for Industries :- |

| Packaging Industry |

Beverages |

| Cosmetics |

Packed Food Items |

| Pharmaceuticals |

Chemical Products |

| Automobile parts |

Electronic Components |

| Eggs |

Pipes & Tubes |

| Cables & Wires |

Plastic |

| Glass |

Wood |

| Paper Ceramics |

Metal Industries |

|

|

| Features : |

|

- The machine body is made of robust stainless steel material.

- Machine can be operated under wider environment conditions, our Inkjet Printer can be operational under the temperature conditions between 0 and 40 degrees C die to the special heater built in the print head.

- Adaptable and designed to meet extreme working conditions. There is no worry about the highly dusty environment to operate this machine.No external air compressor is required.

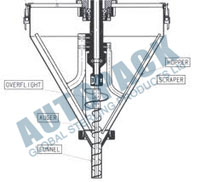

- As our print head has been designed so compact that printing on various shaped products is easily possible.

- Our special “Interval Mechanism” which automatically re-circulate the ink even during non-operational time and so it eliminates risk of nozzle blocking due to dried ink for the use after a long non-operational condition.

- Prints consistently high quality images even on structured and uneven surfaces.

- Print features include Date, Time and Batch number, Logo and Barcode, Trademark.

- Easy to integrate at any position of the production line.

- User friendly interface and most reliable ink system.

- Easy to Operate and almost negligible breakdown.

- Our sales network and service backup system is throughout Nigeria. Our technical and support engineering team are always ready to respond and support customers.

|

|

|

|

|

|

|

|

|

| Specifications : |

| Printing method |

Continuous type Charge control system)Ink Jet Printer |

| Letter height |

1-10mm |

| Printing speed |

Maximum 2,000leters/sec (at 5×5dots font, letter interval of 1 |

| Printing objects |

Paper, metals, plastics, glass, wood etc. |

| Ink |

CN1black (mild solution-based black ink)CN5black-A1(MEK-based super-adhesive black ink)CN505black (Oil-resistant and super-adhesive black ink)

CN101black (Fast drying black ink) |

| Letters |

Alphabet (large/small letter), figures,symbol, hiragana, katakana, kanji

(JIS first and second standard), user registered letters, simplified Chinese

characters (GB2312) |

| Printing lines and dots construction |

5×5:1-4 lines7×5, 7×8 dots:1-3 lines12×10, 10×8, 9×7, 9×9 dots:1-2 lines

24×24, 24×18, 16×12, 16×16 dots:1 lines |

| Fonts |

Ming-cho, Block |

| Number of message |

Maximum 50 messages can be registered. |

| Date, Time (Exp. Date) capability |

Dominical year, imperial era name, Year month date, day of the week, time(12/24

systems), Number of the days and weeks through the year, Beginning, Middle

and later in the month (Period can be adjusted., AM/PM, assignment of

letters (assign letters to the numbers of date |

| Numbering capability |

Maximum 8 lines, voluntary initial number, up/down, carry, (1 count can

be set 1-9999 works), zero suppress (substitute high-order zero by space),

assignment of letters (assign letters to the numbers) |

| Communication method |

RS-232C Maximum38400bps |

| Head cable |

3.5m |

| Nozzle diameter |

50µm |

| Data input |

Full keyboard, RS-232C communication |

| Dimension |

Body: Height 674mm×Width 450mm×Depth 300mmPrint head: Height 40mm×Width 40mm×Depth 199mm |

| Use environment |

0-40ºC 10%-80%RH No dew condensation) |

| Power |

AV220V 50/60Hz 70W (100VA)AV230V 50/60Hz 70W (100VA) |

|

|