|

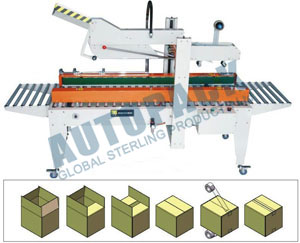

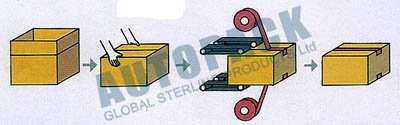

• Sealing different sizes of cartons without adjustment, it will be fitted automatically.

• The sealing pressure is adjustable, according to the different materials of cartons.

• The pushing strength of the movement arms on two-side can be regulated according to the weight of cartons.

• Two-side movement arms adjust the objects packaged to the right position automatically.

•The movement frame is driven by double air-jar, smart and smoothly, using long time.

• The 25kg carton can be conveyed steadily by large power convey motor.

• Pneumatic and electric parts combine perfectly, with convenient and simple operation.

|