|

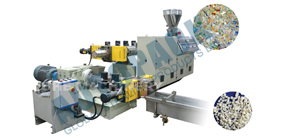

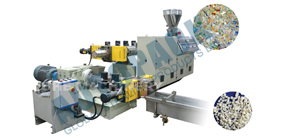

Double Layer Plastic / Thermoforming Sheet Extruding Machine |

|

Description :-

Double layers plastic sheet extruding machine is mainly used to produce various top grade sheet of PP, PE, HIPS, ABS and EVA.

Plastic sheet extruding machine is for making PP & PS sheet for thermoforming machine to make plastic containers, like disposable cups. It is applicable in producing various kinds of plastic sheets of PP which are used for making drinking cups, ice-cream cups, jelly cups, beverage mugs, stationary & office supplies and other packaging vessel as well.

|

|

| |

|

|

| |

|

Glass / Trays Making Machine / Thermoforming Machine for Cups |

|

Description :-

Plastic thermoforming machine adopts the most advanced thermoforming machine technology and was developed to be a forming machine of high production efficiency. It is a combination of mechanical, Electrical and Pneumatic components, and the whole system is controlled by micro PLC. The machine has man- interface operation and combines Heating, Forming, Cutting and Stacking into one process.

|

|

| |

|

Vacuum Forming Glass / Trays Making Machine / Vacuum Forming Machine for Cups |

|

Description :-

BOPS thermoforming machine is a combination of mechanical, electrical and pneumatic components and the whole system was controlled by a electric panel, which can be operated in man machine interface. It combines the material sending, heating, forming and cutting into one process. It has three operation models manual semi-automatic and automatic.

|

|

| |

|

|

| |

|

|

| |

|

Automatic Cup Stacking Machine / Plastic Cups Arranging Machine |

|

Description :-

Automatic Plastic Cup Stacking Machine is an assistant cup overlapping fitting for plastic cup thermoforming machine. It uses the machine transporting fitting and the structure of the cup, transports the cup after being formed by the cup making machine to the appointed cup overlapping part to overlap the cups, the height of the cups being overlapped can be adjusted to control the number of the cups according to the requirement.

|

|

| |

|

Plastic Waste Sheet Grinding Machine / Plastic Sheet Crushing Machine |

|

Description :-

The SCRAP GRINDER are commonly used by almost all the plastic processing industries like injection moulding, Thermoforming, Blow moulding, Rotomoulding, Thermoforming Cast film, PVC, UPVC, HOPE, LDPE, PP Rigid and flexible Pipes and Articles manufacturing plants to recycle the plant waste and rejected articles during manufacturing process. And also the polymer waste recycling plants.

|

|

| |

|

Plastic Granules Mixer / Plastic High Speed Mixer |

|

Description :-

Our range of high speed mixers are specially designed to meet the mixing usage demands of granules with pigment paste or pigment powder or different colored granules, thus achieving uniform blending and mixing. It is also provided with thermo couple to monitor the temperature while mixing operation.

|

|

| |

|

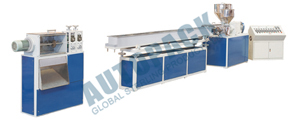

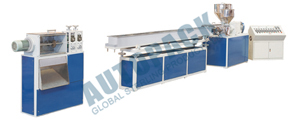

Plastic Granulators Machine / Plastic Re-Cycling Granulators |

|

Description :-

To meet the precise demands of clients, we engineer and supply a wide range of Single screw plastic granulators. These products are extensively acclaimed for special screw design and optimum performance. Our machines are suitable for ABS, polythene, polypropylene and other allied products.

|

|

| |

|

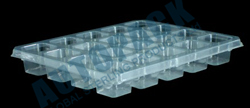

Thermoforming Machine / Moulds Plastic Cup / Trays Moulds |

|

Description :-

We supply all types of thermo forming industrial mould as per the customers’ specifications, to produce accurate shapes and size. Our thermoforming moulds and vacuum forming moulds are made using latest technology (CAD/CAM).

|

|

| |

|

Drinking Straw Making Machine / Plastic Straw Extruder |

|

Description :-

Used in Production of Drinking Straw, Cotton Buds Stick, Lolli-Pop Stick, Ball-Pen Core, Toy Tube, Drop Tube, and other industrial small shaped Pipes

PP Straw making Machine is ideal for small production. The system is also suitable for extruding straws, refluxes and most small diameter tubing and a wide range of industrial applications.

|

|

| |

|

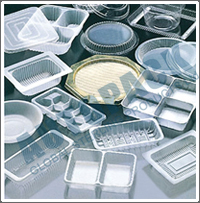

Vacuum Forming Machine / Blister Forming Machine |

|

Description :-

Used in Production of Sweet Boxes, Dry Fruit Trays, Biscuit Trays, Chocolate Trays, Meal Tray, Cosmetic Tray, Burger Boxes, Ampoules Tray, Partition Trays, Egg Trays and also can be used for blister forming for varieties of food, pharmacy and consumer products such as batteries, pencil cell and tooth brush etc.

|

|

| |

|

Semi Automatic Vacuum Forming Machine / Semi Automatic Blister Forming Machine |

|

Application:-

Used in Production of Sweet Boxes, Dry Fruit Trays, Biscuit Trays, Chocolate Trays, Meal Tray, Cosmetic Tray, Burger Boxes, Ampoules Tray, Partition Trays, Egg Trays and also can be used for blister forming for varieties of food, pharmacy and consumer products such as batteries, pencil cell and tooth brush etc.

|

|

|

Production Samples

|

|

|

|

|

|