|

Continuous Inkjet Batch Coding Printer

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Industrial Chillers

|

||||||||||||||||||||||

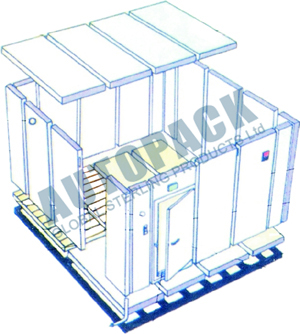

Cold Rooms, Cold Storage Room

|

|||||||||||||||||||||||||||

Ice Cubes Making Machine, Cube Ice Machine

Tube Ice Machines

|

|||

Features & Benefits of ICEBERG Tube ice machine are as follows: |

|||

| – Capacity from 1.5-55 tons/24 hours

– Packaged type equipment for 1.5 – 5 tons capacity – Good shape tubes and arrange on various sizes – Ammonia/ R22/ environment friendly refrigerant – Operate with high temperature make up water – Eligible to install in ambient temperature – Easy and low cost maintenance. – Simple to operate, long life and low energy. |

|||

|

|||

|

|||

Automatic Shell Ice Machine

|

||||||||

|

||||||||

|

||||||||

Automatic Ice Flake Machine

|

||||||||

|

||||||||

|

||||||||

Semi Automatic Ice Block Making Machine

|

|||

|

Ice blocks, standard sizes are: 4.5kg = 11.5 x 9.5 x 48cm 12.5kg = 15 x 13 x 70 cm 20kg = 25 x 13 x 70 cm 25kg = 30 x 13 x 70 cm

These blocks allow easy handling, they are neither too long, nor too heavy.

Production Capacity is available from 200kg – 2 Ton per day. |

|||

Features: |

|||

| – Copeland Refrigeration System to guarantee performance

– Thick enough heat insulation for water tank – Aluminum alloy made ice module – Customized ice size and cycle quantity – Water/air cooling for choose – Easy to Operate and Maintain – Refrigeration equipment supplier with rich experience – One stop solution for all cold chain equipments – We adopt high quality components to guarantee the quality – Professional team for solution installation and after-sale service.

We also provide different kinds for different purposes including Ice Cube Machine, Flake Ice Machines, Tube Ice Machine, Shell Ice, Industrial Chillers and Cold Rooms. |

|||

|

|||

|

|||