|

Shrink Wrapping / Packing Machines

|

|||||||||||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||||||||||

Induction Sealing Machines

|

||||||||||||||

|

||||||||||||||

|

Induction Sealing Machine – Hand Model

Induction Sealing Machine – Air Cooled

|

||||||

Applications :- |

||||||

ChemicalsInsecticides, Pesticides, Adhesives, Photo Chemicals, Flux, Household Cleaning Products AutomotiveCoolants, Lubricants, Break Oil. DairyMilk, Yogurt. CosmeticsCreams, Scrubs, Shampoos, Lotions, Hair Oil. DentalToothpaste, Filling Cement. Health CareNeutracueticals, Herbal Powders PharmaceuticalsTablets, Capsules, Oral Suspensions, Syrups, Dry Syrups. FoodJams, Edible Oil, Food Flavors, ketchup, Lozenges, Confectionary, Salad Dressings, Pickles, BeveragesPowder Drinks, Flavored Milk, Juices, Fruit Syrups, Coffee Concentrate, Tea Leaves.

Benefits Of Induction Cap SealingBetter Quality• No Leakage • Increased Shelf life • Tamper Evident Higher Productivity• Suitable for automated lines • Conveyorized production possible Reduced Costs• No product recalls • Uniform sealing • No operator required |

||||||

|

||||||

Specification : – |

||||||

| Voltage: 220V/50-60Hz

Power: ≤1,500W Capacity: 0-12m/s Sealing diameter:50-130mm Suitable height of bottles: 40-300mm |

||||||

|

||||||

|

Induction Sealing Machine – Water Cooled

|

||||||||||||||

Applications :- |

||||||||||||||

ChemicalsInsecticides, Pesticides, Adhesives, Photo Chemicals, Flux, Household Cleaning Products. AutomotiveCoolants, Lubricants, Break Oil. DairyMilk, Yogurt. CosmeticsCreams, Scrubs, Shampoos, Lotions, Hair Oil. DentalToothpaste, Filling Cement. Health CareNeutracueticals, Herbal Powders PharmaceuticalsTablets, Capsules, Oral Suspensions, Syrups, Dry Syrups. FoodJams, Edible Oil, Food Flavors, ketchup, Lozenges, Confectionary, Salad Dressings, Pickles, BeveragesPowder Drinks, Flavored Milk, Juices, Fruit Syrups, Coffee Concentrate, Tea Leaves. Benefits Of Induction Cap Sealing Better Quality• No Leakage • Increased Shelf life • Tamper Evident Higher Productivity• Suitable for automated lines • Conveyorized production possible Reduced Costs• No product recalls • Uniform sealing • No operator required |

||||||||||||||

|

||||||||||||||

Features : – |

||||||||||||||

| 1, Full stainless steel structure, digital display, split structure, ease of use;

2, Water cooling circulation system, keeping the power of components at a desirable temperature range for more reliable & continuous operation; 3, Under/over-voltage protection, over-current protection, overheat protection, etc; 4, High sealing power, fast sealing, designed for high-speed process lines. |

||||||||||||||

Specification : – |

||||||||||||||

|

||||||||||||||

|

||||||||||||||

|

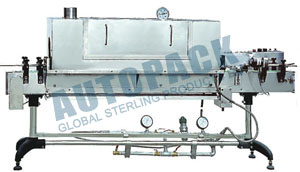

Rotary Shrink Tunnel

|

||||||||||||||||

Specifications : – |

||||||||||||||||

|

||||||||||||||||

|

||||||||||||||||

|

Steam Label Shrink Tunnel

|

||||||||||||||

Specifications : – |

||||||||||||||

|

||||||||||||||

|

||||||||||||||

|

Label Shrink Tunnel

|

||||||||||||||||

Specifications : – |

||||||||||||||||

|

||||||||||||||||

|

||||||||||||||||

|

Automatic Pusher / Sleeve Wrapper With Tunnel

|

||||||||||||||||||||||||||||

Characteristics: – |

||||||||||||||||||||||||||||

| • It is connected to the production line through feeding conveyor

• Up and down magnetic switches to protect the operators from accidents. • The input position is adjustable, base on the size of products packaged. • Big conveyer motor with stepless speed regulating, ensures smooth feeding. • Up and down large power fan system ensures the excellent effect of shrinking in one time. • Super cooling system cools the packing to make the film more durable. |

||||||||||||||||||||||||||||

The size of the machine can be customized as per customer’s requirement. |

||||||||||||||||||||||||||||

Specifications : – |

||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||

|

Sleeve Wrapper / Applicator With Tunnel

|

||||||||

|

Characteristics: – |

||||||||

| • Up and down magnetic switches to protect the operators from accidents.

• The input position is adjustable, base on the size of products packaged. • Big conveyer motor with stepless speed regulating, ensures smooth feeding. • Up and down large power fan system ensures the excellent effect of shrinking in one time. • Super cooling system cools the packing to make the film more durable. |

||||||||

The size of the machine can be customized as per customer’s requirement.

|

||||||||

Specifications : – |

||||||||

|

||||||||

|

||||||||

|